Have I mentioned lately that woodworkers are some of the most opinionated and set-in-their-way people who you will ever have the good fortune to meet? If you are a professional woodworker, then yeah, I am probably talking about you. If you are a beginner, be warned! We are going to discuss when to NOT use pocket hole screws!

(This post may contain affiliate links (*). That means that I make a small commission from sales that result through these links, at no additional cost to you. You can read my full disclosure here.)

Asking a simple question from a group of woodworkers will garner you dozens of opinions, and is likely to end in a heated debate where names may be called and lineage may be questioned. If you don’t believe me, toss a question out on a woodworking board or forum, any question, and wait for the tide to roll in.

Okay, so I am exaggerating just a bit. But seriously, we are a passionate lot with our way of doing things and a tendency to poo-poo anything that is not up to our standards. Because I grew up being taught by, and sometimes disagreeing with, my grandfather on woodworking techniques, I have tried to stay open-minded about things that are new or different.

And because I have this love for teaching others to create their own pieces, I am not quite so snobbish about making something the easy way. Most people do not have the benefit of years of experience to draw on to build something. Even more, people just want to make something on the cheap and quick.

Which brings me to my topic for this post – when to use pocket hole screws. You see, there are many woodworkers out there that do not like nor use pocket hole screws for woodworking. And when they do, they restrict the use to a few mundane tasks.

However, pocket hole screws have become the mainstay of the beginner woodworker and the DIYer. So, rather than ignore their potential, I have embraced the ease and simplicity that they bring to most projects. In fact, if you browse through my archives, you will find a lot of things that I have built with my Kreg K5* and my Kreg R3 jigs.*

But, and this is a big but, there are times when I am completely against their use, and when I find it unprofessional to recommend them. So, let’s discuss when to not use pocket hole screws!

If It Will Be Visible…

This one may be obvious, but you should avoid using pocket holes in locations where they will be visible. The only exceptions to this would be 1) if you don’t care about the aesthetics of the piece, or 2) you are using plugs and will be painting the piece.

Table Top Assembly…

This one has got to be my biggest pet peeve. I see people doing this all over the web and it just makes me cringe. You know what I am talking about – those DIYed farmhouse tables where they use pocket hole screws to assemble the table top.

I’m not saying that you can never use pocket hole screws for table builds. After all, I do have a console table on this blog that was built with pocket hole screws. But, I am saying that you should be aware of the results and build accordingly. I also would recommend that you never use that method for a dining table top.

If you see someone building a dining tabletop with pocket hole screws, let me just tell you that you may want to move on. If you have done this yourself and are now offended that I have knocked your build-up, please let me explain it to you before you close me down.

Wood moves. It always has and always will, and when it moves it does so mostly across the grain or width of a board. You can’t stop it from moving, and if you try you will only cause damage to the wood. Best construction methods will take wood movement into consideration and work with it, not against it.

Yes, you can build a tabletop using pocket hole screws, but it will eventually separate and possible develop cracks and/or splits. In addition, you are really just creating more work for yourself by doing it that way.

The proper way to connect solid wood boards into a solid piece along the vertical (length) is to use glue. Yes, just glue. Glue is as strong as the wood itself, so don’t be afraid to rely on it by itself. Glue will also allow that wood to expand and contract as the seasons change.

On the other hand, pocket hole screws will bind areas of the wood across the grain. Picture if you can a dry sponge. Now, if you pinch a section together with your fingers and then hold the sponge beneath the water, what happens? The sponge will expand, but the area beneath your finger will remain held in place.

In fact, you will likely see that the sponge will expand fully in the area that is farthest away from your fingers and less so as you get closer to where you are pinching the sponge. This is sort of what happens when those farmhouse tables start to move.

What If I Use Glue AND Pocket Hole Screws?

Well, that would be better, but I would still caution you on this. Most of the time this is done as an alternative to using clamps. You add glue and then screw it and you’re ready to move on to the next step.

However, inserting those screws without clamps holding everything in place can cause the boards to shift out of alignment. And, if you are going to clamp everything in place, why not just use the glue-up method and save the time and expense of the screws.

Bread Boards…

My second pet peeve about pocket hole screws is when they are used on the breadboards. If you are asking yourself, “what are breadboards?” No, it is not something that you set on your counter to slice bread. It is those two pieces of wood that are located at the ends of a table.

In addition to the people using pocket hole screws to assemble a tabletop, I often come across people attaching breadboards to those tables with pocket hole screws, as well. I assume they have seen a table somewhere that they want to duplicate, and they set out to build one without really knowing the construction purpose for each part of a table.

Breadboards are not just placed on a table because it looks nice, it is there to encapsulate the exposed ends/grain of the tabletop and to allow for them to move. When you use pocket hole screws to attach a breadboard to the ends of a table, you are inhibiting that action.

This is the number one reason why so many of those DIYed farmhouse tables develop cracks. The Woodwhisper had a nice little article about wood movement that I believe to be helpful for beginners. So, you may want to check that out, too.

However, the proper way to attach a breadboard is to use mortise and tenon joints. Now, I know that may be out of the range for some people’s skill. But, keep in mind that a farmhouse tabletop doesn’t have to have a breadboard. But, if you plan to attach one, maybe this is a good time to learn how to do something new and expand your abilities.

To Attach TableTops To Aprons…

Another big no-no for building tables is that you shouldn’t use pocket holes for attaching the tabletop to the apron. Again this inhibits the movement of the wood. There are several options to get your attachment done correctly, and they are quite easy.

I prefer to use figure 8 connectors* just as I did for my kitchen island. The reason that I like these is that as the wood moves in different directions the figure 8 swivels in its groove. I also love these because they work well as hidden hangers, which you can see in my post on building honeycomb shelves.

If figure 8 connectors aren’t your style, then you could also use tabletop clips. They work in a similar fashion as the figure 8 connectors,* but you will have to create a groove in the apron for these to sit. Another option is to make your own connectors. Just make sure that you make them in a way that allows for the tabletop to move.

Cabinet Doors or Drawer Fronts…

When building a cabinet door or a drawer front, the rails and stiles should be assembled with tenon and groove connections. I am not talking about the cabinets or drawers themselves, just the doors and drawer fronts. I have seen a lot of projects out there showing doors built with pocket holes, and while this isn’t structurally an issue like the tabletops are, it still screams amateur.

Now, there is nothing wrong with being an amateur. We all start at that point. So, if you have doors that you built with pocket hole screws, don’t worry about it. As long as you are happy with the outcome, leave them be.

However, for your next project, you can always up your game and get those professional quality doors. To see how to build a cabinet door, I refer you to my shaker doors. I know that you are saying to yourself that you don’t have the tools to do that sort of thing. But, you can create those tenon and grooves without tools.

Take, for example, my Christmas easel. My construction method was just for the purpose of showing others how to properly create joints, even when you don’t have power tools. Take a look at that post/video and apply those same concepts to your next set of cabinet doors.

Melamine or Particle Boards…

Working with melamine and/or particle boards can be an incredible PITA, especially if you are new at it. I recently posted all of my tips and tricks for building with these. So, I recommend that you read that for an in-depth explanation on getting the most of these materials.

I know that some of you have probably already used pocket hole screws on melamine and didn’t suffer any ill effects. So, why is it an issue?

Well, while you can probably get away with using pocket holes for some projects, anything that will receive day-to-day use is likely to come apart. Melamine and particle board requires special screws for construction. And, if you have ever purchased any assemble-at-home furniture, you have probably seen that these pieces always use cam locks and dowel pins for their construction.

They don’t manufacture it that way because it is easier, and they certainly don’t do it because it is cheaper. In fact, if you could use pocket hole screws with melamine, I bet Ikea would have switched over a long time ago. They simply don’t do it that way, because they know it wouldn’t hold up.

Across The Grain…

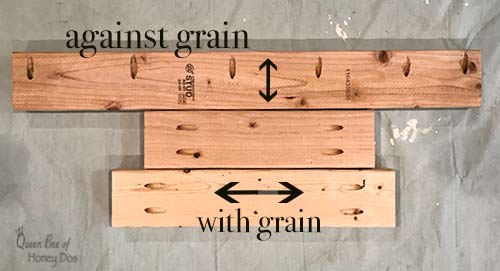

Finally, because I can’t cover every possibility in this post, I just want to say that when you are building anything with pocket hole screws, consider the grain. If you are going across the grain of solid wood with a pocket hole, it is possible that you will be restricting movement.

Since most pocket holes are placed at the end of a board or into plywood, we usually don’t have to worry about movement with pocket hole screws. But, if you are going against the grain, evaluate your piece to determine if restricting the movement is going to be an issue.

Final Comments…

Now, if you have used pocket hole screws in one of the ways that I say you shouldn’t, I hope that you aren’t offended by my post. I am certainly not one of those bloggers that lives off controversy. Nothing here is meant to put down anyone else’s efforts.

I also am not here to malign any other woodworker. I fully admit that there are different ways to construct with wood. I also fully admit that my way is not always the best way. I am just here to help and offer what I know from my years of experience. So, I hope that you are able to take something useful away from this post.

– PIN IT –

Laura Griest says

I never comment on any blog posts but I absolutely had to with this one. THANK YOU for writing such a helpful and respectful post! I recently came across a forum that was discussing the same topic, and the way it was written was incredibly disheartening for me as a beginner. Of course I want to learn how to do things the right way, but not everyone can grow up being mentored by an expert or take years of expensive classes to perfect their craft. Instead, many of us work hard to teach ourselves, trying to filter through the tons of misinformation out there in order to develop our own curriculum, so to speak. Based on everything I’ve learned to date, this blog post is spot-on and does so in a way that teaches rather than scolds! I found it very informative and greatly appreciate you taking the time to share.

Rachel Lynn says

Thank you Laura,

I am so glad you decided to leave a comment! I understand exactly what you are saying, and I am thrilled that you found my post to be helpful.

Lindie Lloyd says

I agree! This was a great article. I am also a beginner and I am learning more or less from “experts ” online. lol I recently built a farmhouse tabletop and per directions used pocket holes and was sad when it developed a crack and 2 splits within a few weeks. Well, now I know why and I appreciate the information. I will rebuild it the correct way this time. Thank you!

Rachel Lynn says

Your welcome. Good luck with your next build!

tom flemer says

OK Mrs. Open Mind, I really appreciated your thoughtful analysis of using pocket screws. Not for or against pocket screws, I just don’t think about using these very often. From your post I realized that I had committed two offenses on a previous DYI project.

About five years ago, I built a skinny partition using primarily two pine louvered doors and architectural grade 4S pine. The doors filled most of the opening, however, filler panels were needed to complete the partition. The uprights are 2-1x6s glued up and trimmed to 4-1/2”. Quarter round was used to seat the panels. The panels were attached to the uprights with pocket screws from the backside of the panel. Although visible, my rational at the time was to make disassembly obvious. Such as when wall painting is needed, the partition can be removed without a five pounder. Well, that’s for me. A future owner should see also, unless they are from the school of HGTV design, where everything is done with a sledgehammer. The second offense was to place screws with the grain as shown in your post. The partition is six feet from an exterior door, so gets blasts of hot, cold, high and low humidity every day. The quarter round hides the edges of the panels. No visible gapping, nor has the panel checked. I am thinking, I will not be around to see if the partition lasts 100 years.

To recap what I got from your post, that the challenge and fun of DYI design and fabrication is figuring out how to get desired results with available materials and tools. A Kreg pocket screw jig is a low cost and less space consuming that a large piece of powered equipment. I need keep the pocket screw jig in mind on future projects. Moreover, I now know when I am crossing the line and if the results will work in the long term.

Rachel Lynn says

I love your recap! And I agree, the pocket hole jig is great, cost wise and space wise, and I recommend everyone have at least one. It sounds like you put some thought into your partition, but I am having a hard time picturing it in my head. But, if I am reading this right, any seperation would be hidden by trim.(?) I’ld love to see it. Feel free to email it to me, and we can have a more productive chat.?

Rhoda Hiller says

Thank you for such a helpful article. I use pocket holes to attach my craft items to their bases. I make fall and winter outdoor items (scarecrows, snowmen, santas). The pocket hole works very well but I had considered making a table so I am glad I read your article. I also make benches and will adjust the use of pocket holes to the ends of wood with the grain.

Susan Musick Story says

Thank you so much for this great information. Of course, now I am cringing thinking of the things I have built for people as gifts from plans that used pocket hole screws on the tops and door fronts. Lesson learned and time to expand my beginner building knowledge.

Rachel Lynn says

Susan,

Your very welcome. And, I am sure they loved the gifts. ?

Tom Henning says

I agree there are projects where pocket holes don’t belong. Even in natural finished wood, properly spaced plugs can be a great design element. I am just finishing my kitchen, cabinets designed and built by me, built with pocket holes and 3/4″ Maple plywood. Doors are 3/4″ Poplar, holes are filled with 3/8″ dowel rods purchased at Home Depot. This is much cheaper and they fill the holes more completely. I just use my Multi-Tool to cut them and sand down. I MDF for the panels, sprayed with Sherwin Williams Emerald Urethane and they look GREAT. BTW, the holes don’t show. One last word, the key is to build a work table that is 100% SQUARE, keep it clean, use a table saw sled that is 100% square and your job will be golden.

Rachel Lynn says

Tom, it sounds like your kitchen is going to be the bomb! Love the Emerald paint, too. I just switched over about a year ago from using their ProClassic. Congrats on a project well done!

Tom Watts says

So y’all like Emerald Urethane over Proclassic Hybrid, Acrylic, or Oil base? I’ve only used urethane for decks & floors, and either Ben Moore Advance or the ProC. Hybrid for cabinets. I find ProC hybrid to be one of the smelliest of that type, and usually opt for the Advance. But what is the advantage of the urethane?

Rachel Lynn says

I can only speak for myself, but I just like the feel of it. I also like the the durability. However, I am also a big fan of the Proclassic. Of course, I generally allow my cabinets to sure for about 4 weeks before they go in, so I can’t say how well it might perform if subject to immediate mistreatment.

Patrick says

Does this also apply to dowels for table tops?

Rachel Lynn says

Patrick, In what sense? Dowels are used as both joinery and as a guide for alignment. They do not perform the same way as pocket hole screws and are generally fine for use in the above examples. I wouldn’t use them for breadboards though, but other than that just keep the movement in mind.

Mark says

Hi Rachel, thanks for the article it was very useful, I recently built a table top using glue and biscuits and added cross beams for extra support. This has also developed cracks, the metal legs also had a cross beam

Any idea what I did wrong? I need to rebuild it and didn’t want to make the same mistake

Many thanks

Rachel Lynn says

Mark, This is just one thing that can cause cracks. There are so many others. Without seeing the table, I can only guess, but how is the table attached to the base? Anything that binds the movement can cause cracks. Also, was the wood cured or fresh sawn? High moisture will result in shrinking and pulling away from the joints as it dries. What’s the environment like where the piece lives? High humidity? If so, how was the bottom finished? If left raw and moved from a low humidity environment to high, an unfinished bottom will take up moisture at a faster rate than the top. So many things could be the issue, but think in terms of moisture. If you like, you can email me with more details and images. ?

Mark says

Thanks Rachel, my email address is (edited by moderator) if you could email me I’ll explain more snd send pictures

Rachel Lynn says

Mark, You’ll find an email form by clicking “contact” under the Resources tab. This is where you can send images to me. I removed your email address from your comment to prevent it from being lifted by a bot. They frequently scrape addresses from the internet and I don’t want you to put yourself at risk. ?

Bruce says

I agree with you 100% on when to use pocket holes. How do you feel about biscuits? I just finished a display cabinet for my daughter and used only biscuits. No metal fasteners at all. Just wanted to see if I could do it.

Rachel Lynn says

I like to use biscuits when I want some assistance with alignment. They are great for that, but I don’t feel that they add any significant strength to a typical glue-up. Some people swear by them, and some people scoff. Yet another thing for us woodworkers to have heated discussions over. ?

Dean says

Hi Rachel I am a newbie into the carpentry area and I’m confused as to when to use pocket screws versus regular screws.

Also Did I read correctly when you said glueing lumber together is stronger than screwing them?

Thank you

Rachel Lynn says

Dean, Pocket hole screws are designed specifically to be used inside a pocket hole. Most “regular screws” should never be used in a pocket hole. In addition, there are many types of regular screws – wood, metal, machine, etc. Each has its place in construction and would be too in-depth to address in the comments.? As far as the strength of the glue, let me be clear. When doing long edge grain to long edge grain glue-ups as mentioned above (i.e table tops) glue will always be stronger than the wood itself. Therefore, it will perform better than the mechanical strength of screws. However, end to face grain (butt joints) would not be as structurally sound. This is why we use pocket holes, tenons, lap joints, dovetails, etc. for those types of connections. Good luck with your carpentry, and keep asking these types of questions!

Chris says

Just read your article on when not to use pocket screws. I have used all 3, clamps, screws and glue on tabletops. I now know not to use the screws.

Anxious to read your other articles.

Thank you!

RW says

Rachel, I’d read this before, and just came across it again… did I make a big mistake? I just used pocket hole screws to join the long beveled edges of some 1×6 finger-jointed pine. (Pre-primed. Maybe the finger joints and priming will help lessen future wood movement?)

We have a large bay window. We had to install pairs of 1×6’s (two vertical casings) at 30 degree angles where the bay window turns each corner around the wall. We first beveled the boards at 15 degrees, then used three or four pocket holes along the back side (hidden against the drywall) to hold the pieces together at the right angle while we installed them. Installing an angled set like this was a lot easier than trying to get the angle correct with two loose pieces. Then we used brad nails on the outside front edges of the reveal to fix the casings in place. Are we in trouble in the future? Thanks!

Rachel Lynn says

RW, it is really going to depend on the humidity fluctuation in your home and how acclimated/cured the casing was before being installed. You are probably going to be okay. But if you start to notice cracking within the wood or along the fingers, you will want to carefully take the casing down and remove the screws to provide some relief. However, if you only notice separation along the seams, just leave it be for a full year. Then, you should be able to caulk the seams with a flexible caulk and repaint. In the future, you can use construction adhesive to hold the pieces in place on the wall. This will allow you to make slight adjustments to the fit prior to nailing and will not cause stress fractures in the wood.

Luis Parker says

Wow! Nice job on this one. I, myself use pocket hole screws a lot and I agree with you. We all have different opinions on this one. I’ve learned a lot from this blog. Thank you for sharing this with us.

Steven Porter says

Late to the party, but great info. Thanks!

Bob says

Rachel,

Guilty as charged! In 2017, I built a Farmhouse dining table for my son and daughter-in-law using pocket holes for the table top and the breadboard ends following an online tutorial. At her request, her parents provided the lumber. It was the framing members salvaged from the demolition of their 75 year old garage that had to be replaced. The builder carefully selected pieces that had never been exposed to water. Due to it’s age, it was full size lumber, not dimensional. Each required an uncounted number of passes through my thickness planer (checking the wood with a metal detector first, I also found that the builder had also removed all nails).

The table is beautiful and shows no signs of cracking at this time. I was there 3 weeks ago (for my grandson’s 3rd birthday party) and checked it thoroughly.

I am hoping it’s age and that it is now in a conditioned environment gives it some protection.

Rachel Lynn says

Bob, you certainly aren’t the first one to build a table this way. If environmental conditions remain steady, the movement may be so minimal that damage won’t occur. We’ll just keep out fingers crossed. 🤞🏻😉

Hendrik Vink says

Hi Rachel, very much to the point, no bulls%&t or sugar coating your views and experience. I very much appreciate that. I consider myself an intermediate builder, I stick to rustic style furniture and according to your advice…..I feel like I’ve made a few mistakes in the past but also I’m grateful for passing your knowledge on. We can be a bit cocky with our work for sure but sensitivity only stops us from getting to the next level, thanks for your article and it was enough to allow me too both feel good about my work as well as a bit….well a few learnings lol. Take care and keep the knowledge coming

steve says

This post is titled “when not to use pocket hole screws”, but this was never answered. You have put only two opinion listing in this post for to never use pocket holes, “if they are seen, and if they are across the grain”. You take a mild stance on the second. I have made many tables with the across the grain plus glue method, and I agree this is for or in spite of clamping, but you have fallen short of giving any real advice to when and when not to use pocket holes. Sorry, this feed seems to be full of positive reviews and thank-you type stuff but no real advise on when or when not to use pocket holes or pocket hole type joints.

Rachel Lynn says

Steve, I am sorry you were unable to find the answer you were looking for. However, there are more than the two instances you listed above. I also state to not use them for melamine builds, for farmhouse style tables, for bread boards on any table, in any table apron to attach table tops, and for cabinet door rails-to-stiles (although that one can pass the mustard). Other than those, there are not a whole lot of times when you can’t. Maybe go back and focus on the post details more than the glowing comments. 😉