Constructing a cutting board is one of the first woodworking projects that most woodworkers like to tackle. However, making (or buying) the right cutting board is different for each person. There are several factors to consider in order to get the best outcome for each user. This guide covers everything that you need to know about cutting boards and butcher block tops and should help you get the best results.

| Table of Contents Best Grains to Use Best Wood Species to Use Wood to Avoid Concerns About Toxicity Finish Options Common Mistakes to Avoid |

Cutting boards and butcher block tops are an obsession of mine. I have a tendency to collect them. Which is probably why I built a knife and cutting board storage drawer. (just a little plug for myself there).

But in all seriousness, there are things that can make or break a quality cutting board.

Understanding how one is built and why it is built that way can really help woodworkers to make a quality product or help a buyer make a good choice.

(This post may contain affiliate links (*). That means that I make a small commission from sales that result through these links, at no additional cost to you. You can read my full disclosure here.)

Best Grain for Cutting Boards and Butcher Block Tops

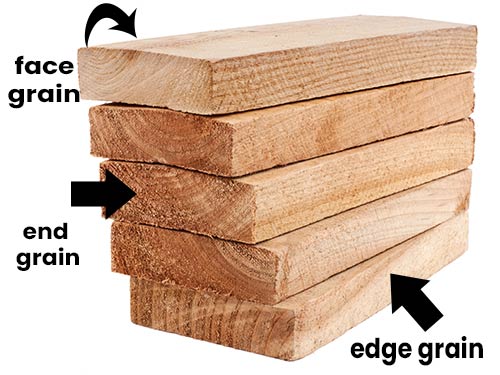

There are three possible options when it comes to the way cutting boards can be built with different pros and cons for each. While butcher block tops generally use just two of the below options, especially when it comes to countertop selections.

Face Grain

The first type of cutting board is made using the face grain. These are the least expensive choice for cutting boards but is rarely ever used for butcher block tops.

A face grain board requires the least effort to build. It is constructed by gluing together the edge grains of the wood planks. It also is often the most beautiful part of a piece of wood and will give results similar to a tabletop build.

However, cuts and dings show up more on the face of the wood. They often result in a thinner cutting board and will need to be refinished more often. That means the boards will not last as long as one of the other options.

Best use for face grain boards: Cheeseboards, food trivets, pastry boards, display boards, or other decorative uses.

Edge grain

This is the construction technique that is most often seen in butcher block tops. It is constructed by gluing the face grains together.

Edge grain is the middle-of-the-road technique. It is stronger than the other two options, but that means that it is also harder on the knives.

The price point is usually more expensive than a face grain board but less expensive than an end grain version.

Best use for Edge Grain: These are good for any use when constructed to the right thickness. In particular, edge grain boards work well as butcher block tops, everyday cutting boards, and meat cutting boards.

End grain

End grain construction is considered the premium version for cutting boards and butcher block tops. So, you should expect these to be a bit more costly.

They are constructed by gluing the edge grain and/or face grains together which will allow the end grain to be exposed.

These are by far the best option if the wear-and-tear on your knives is a big consideration for you. Because the wood fibers are exposed on the end grain, knives are not met with as much resistance as with the other two options.

In addition, the natural expansion of the end grain tends to allow knife marks to self-heal. This helps keep these boards looking better for a longer period.

However, the end grain boards require the most upkeep. The end grain is not as stable as the other versions.

Because the exposed fibers are the wood’s natural way of taking up water, these are prone to expansion and must be refinished more often.

For that reason, end grain boards should be constructed on the thicker side to allow for more frequent sanding. This means you will need a more substantial piece if you want longevity.

Best Use for End Grain: Butcher block tops, heavy-duty chopping, vegetable boards, high-end quality.

Which Wood Species are Best

When making the decision on what type of wood you want to use in a cutting board or butcher block, the most important question to ask is which is a more important factor to you – longevity of the board or the longevity of the knives being used.

Most will prefer a very long lifespan for butcher block tops because the expense to replace them is quite high.

Others prefer cutting boards that land somewhere in the middle – providing protection for their knives while still standing up to the day-to-day torture.

To make that determination, you can use the Janka Rating scale. The best types will fall between 950 – 1500 on the scale.

These are strong enough to hold up to everyday cutting without damaging the blade of the knife.

Anything lower than 950 will be too soft for normal cutting board use. Anything above 1500 can cause the blades to become dull or damaged.

Wood that Falls Between the Range

Hard maple or Sugar Maple – Next to bamboo, maple is the most common wood used for cutting boards. It is also the most popular choice for functional butcher block tops.

It has a Janka rating of 1450 which places it right at the top end of the desirable range. Choose this material if your biggest concern is the longevity of the cutting board or butcher block.

Bamboo – the most commonly used wood choice for cutting boards. It also makes a nice option for butcher block tops.

Although bamboo is actually a hard grass and not wood, it has a Janka rating of around 1380 (varies slightly by species). This places it just slightly lower in hardness than maple.

Another benefit of choosing bamboo is that it is one of the fastest-growing building materials available. If you are looking for a sustainable material, bamboo is a good choice.

Walnut – Walnut is considered a premium wood and makes some beautiful dark-toned boards. It comes in around 1010 on the Janka scale.

This makes it a prime choice for anyone looking for a happy medium between the longevity of the wood surface and the life of the blades.

Cherry – Cherry is a loved wood for many kitchen applications. It is also at the lower end of the hardness range. Choose this wood if your knives are your biggest concern.

Other species commonly used either as a whole or as accents in cutting boards:

- Curly Maple

- Purpleheart

- yellow Heart

- white oak

- hickory

- beech

- teak

Which Woods To Avoid

Soft Woods

Wood species that fall below 900 on the Janka rating will likely be too soft for a cutting board or butcher block top. The most easily accessible of these are pine, poplar, and basswood.

If you use anything below the recommended Janka rating, you should expect a lot of cut marks and dents to quickly mar the finish.

Open Grain Woods

Wood that has an open grain is not a good choice because it leaves a lot of nooks and crannies for bacteria to get a foothold.

Red oak is the example that comes quickly to mind followed up closely with ash.

While there are different species with different degrees of openness, it is a good rule of thumb to avoid both oak and ash.

Concerns About Wood Toxicity

The questions surrounding the safety and/or toxicity of different wood species need to be addressed.

First of all, it is always a good idea to make sure the wood that you are using is safe.

Keep in mind that there is always a chance that someone somewhere will have a negative reaction to even the safest wood species.

Some wood types are more likely to result in a negative reaction. So, do your due diligence when choosing a species.

Some species have sap and resin that may seep out of the wood and cause reactions. However, this is generally more of a concern with wooden spoons than with almost any other kitchen use.

Some species may result in contact irritation or cause an allergic reaction for the end-user.

Avoiding exotic wood that has yet to be fully vetted and communicating with the end-user about allergies will eliminate most potential problems.

That being said, there seems to be a LOT of misconstrued information floating around about the safety of wood when it comes to chopping boards, butcher blocks, and the aforementioned spoons.

When doing your research, take into consideration the source. Also, take into consideration the situation under which a wood species is considered toxic. Let’s take a look at a few that have gotten a bad rap, lately.

Walnut Toxicity?

Black walnut wood chips shouldn’t be used in landscaping because they contain a substance that is toxic to some plants and can also be toxic if eaten by dogs.

Neither situation applies to cutting boards but has caused quite a bit of confusion.

Another concern is with the issue of nut allergy reactions occurring from wood contact. This is definitely something to be taken into consideration.

However, the allergy-causing ingredient for most people is the protein that is found within the nutmeat and not within the wood itself.

This means that in most situations walnut wood will cause no reaction to those suffering from tree nut allergies.

HOWEVER, woodworkers should always be mindful of the potential for negative reactions in allergy suffers. Communicate with the end-user to make sure there is not going to be an issue. When in doubt, choose a different wood.

Purpleheart

I have also noticed an uptick in discussions surround the safety of using purpleheart in cutting boards. This originally started because of a few reports of occupational allergic reactions.

But, you know how it goes. One person sees a blip somewhere about a reaction and before you know it everyone is repeating incorrect details.

Speaking from experience, I can tell you that purpleheart dust can cause some serious irritation to the eyes and the splinters cause nasty irritation to the skin.

But, as far as the wood causing a problem within a cutting board, it is not likely to occur unless the user has a specific contact allergy to that species. You should keep in mind that contact allergies to wood products are very rare.

Purpleheart is commonly used as an accent in cutting boards. It is a relatively benign wood.

Even with the occupational reactions that I have, I have still built several cutting boards with purpleheart accents without incident. Just remember to use protective wear when cutting it down.

Calm Your Fears

To reiterate, yes there are special circumstances to consider. And yes, there are a few species of wood that are not appropriate for cutting board and/or butcher block top applications.

But in general, the wood you see frequently being used (maple, walnut, beech, cherry, bamboo, etc) has been vetted for years and is perfectly safe for this application.

Much of the confusion surrounding other species of wood comes mostly from people not understanding the difference between occupational risks and the use of the end product.

You should know that when most knowledgeable sites mention wood allergies, they are generally referring to exposure to dust during the manufacturing process.

All wood dust is dangerous, but some pose specific irritant and allergy risks. To find out more about manufacturing risks for a specific species of wood, you can check the wood-database to see which reactions have been reported with different types of wood.

Finish Options

When choosing a finish for your cutting board or butcher block top, keep in mind that you can not just slap any old finish onto the piece. There are a limited number of safe products that can be used on your boards.

Mineral Oil

The most commonly used finish is basic mineral oil.* It is food safe and easy to refresh when needed. Apply a thin layer anytime you notice your wood beginning to dry out.

Linseed Oil

An alternative to mineral oil is linseed oil. However, you must make sure that you are using the correct form of linseed oil as there is some confusion with this product that can cause problems.

First of all, real linseed oil (or raw linseed oil) is actually flaxseed oil. You can get this at any health food store.

However, it has a tendency to darken the wood over time. It also will cause a gummy texture when the excess isn’t removed in a timely fashion.

Avoid using Boiled Linseed Oil (or BLO). There are two types of BLO – homemade and chemically prepared.

The homemade version results in a safe product but the molecules are too big and do not penetrate as well as the raw stuff.

BLO from the big box stores is a whole different can of worms. Most contain a combination of metallic salts and hardeners to replicate the homemade quality. This is not something that you would want to come in contact with your food.

Walnut Oil

Some people like to use walnut oil* on their boards. If that is your preference, keep in mind that walnut oil can cause harmful reactions in people who are allergic to nuts. It is also more expensive than the other options.

Waxes

There are several waxes that are safe for food contact including beeswax, carnauba, and paraffin. When used in combination with one of the above oils, wax can add to the durability of the surface.

You can mix waxes and oils to make your own cutting board treatment, or you can buy one of the many professional versions available.

My favorites are Boos Mystery Oil,* Boos Cream,* and Howard’s Butcher Block Conditioner.*

Generally, I use Howard’s for my regular maintenance on my wooden surfaces.

If the board suffers some unintended damage (such as being placed in the dishwasher by a well-meaning person), I rescue it by doing a combination treatment of Boo’s products.

Another option for a rescue is to use mineral oil and follow it up with a coating of Howard’s. This does a very similar result as the Boo’s combo.

Common Mistakes With Builds

Something that most woodworkers understand is that there are certain things that you can apply to the surface of cutting boards or butcher block tops.

There are also certain things that you shouldn’t apply.

If you search the internet for butcher blocks or even “noodle boards,” you will find a lot of DIYs using stain and/or paint finishes.

Obviously, most of the items are loosely using the term butcher block, and those “noodle boards” are actually just meant to be decorative cooktop covers.

But a less informed person may see something like this and think that it is safe to use.

One of my biggest pet peeves is when someone applies a stain on a “butcher block” top without specifying that they are using it as a standard countertop surface and not as an actual functioning butcher block.

Stains

If you plan to build a functioning butcher block top or cutting board surface, you should never apply a stain to the surface. These are generally not considered safe for contact with food.

When using a stain, the surface needs to be sealed and should be treated in the same manner as a dining table.

Paints

Likewise, paint is not food safe and should never be used on anything where you plan to apply a blade to the surface.

If you want to build a decorative cooktop cover, just know that you shouldn’t use it to chop food or to knead dough.

If you want to have a dual-duty cooktop cover, you can always build a real pastry board or a cutting board for that purpose.

Epoxy

This one is a bit tricky. A lot of people are really into the epoxy cutting boards, myself included. Some are quite stunning.

But, epoxy is a film finish (i.e sits on the surface) which is never recommended on functioning cutting boards.

That’s not to say that it can’t or should not be done. But, you should be aware of the limitations and make those known to the end-user.

As long as the epoxy is a food-safe epoxy, you can safely build a cheese board or a light-duty cutting board.

However, epoxy is not suitable for a board that will see much cutting or chopping. It can chip, crack, or flake off into the food being prepped.

Consider epoxy boards as more decorative in nature and save your real chopping for solid wood boards with traditional finishes.

Final Comments

Sheesh! That was a lot of material for one topic!

And now that I have said everything that I feel needs to be said, I want to end by saying that there are no hard and fast rules for building a cutting board/butcher block except for safety.

Always, always do what is best and safest for the end-user. Always!

Aside from safety, the rest is just preferences. I can tell you until I am blue in the face that an end-grain maple board is the best. But, you may disagree. And if so, you wouldn’t necessarily be wrong.

It’s all really up to what the user needs. That could mean that you build with a wood that I might consider too soft.

It could mean that you use wood that has open grain. There is a whole slew of options and situations that can influence your decision.

In the end, just build (or buy) the best piece that fits your needs. The rest is just gravy!

Please keep it clean. Comments that do not follow the Comment's Policy may be removed.